Prototype one

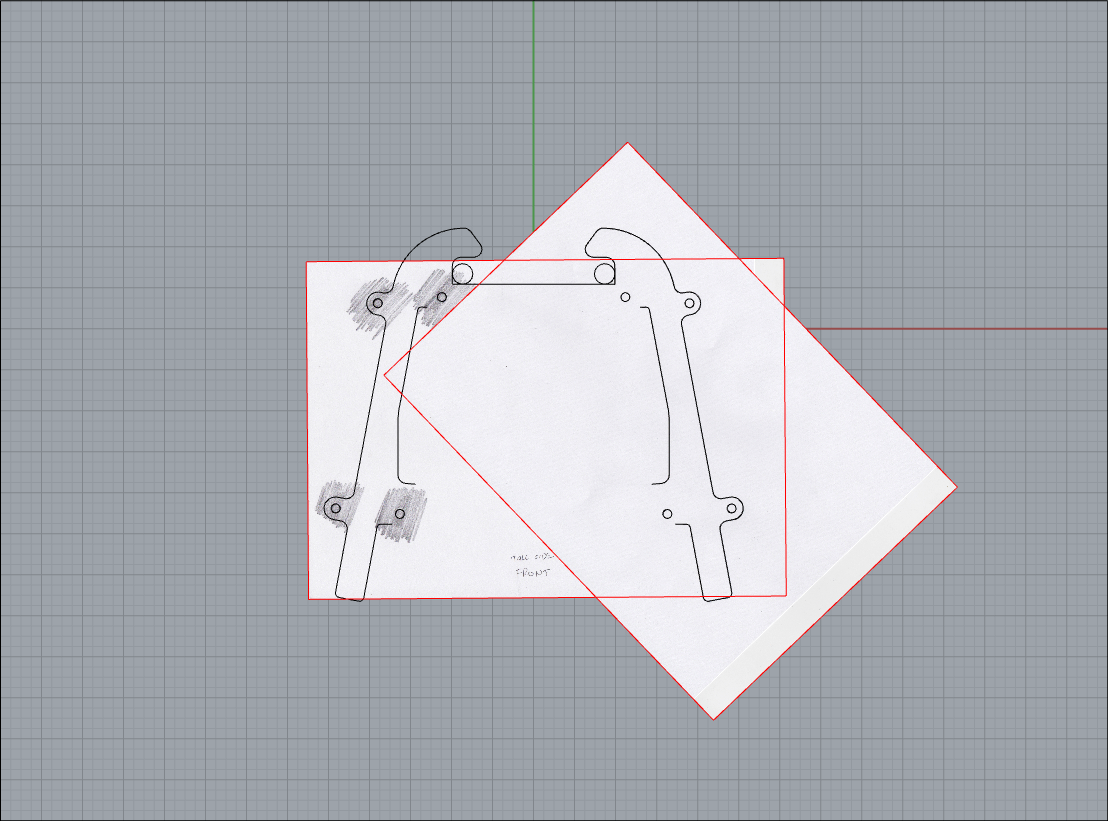

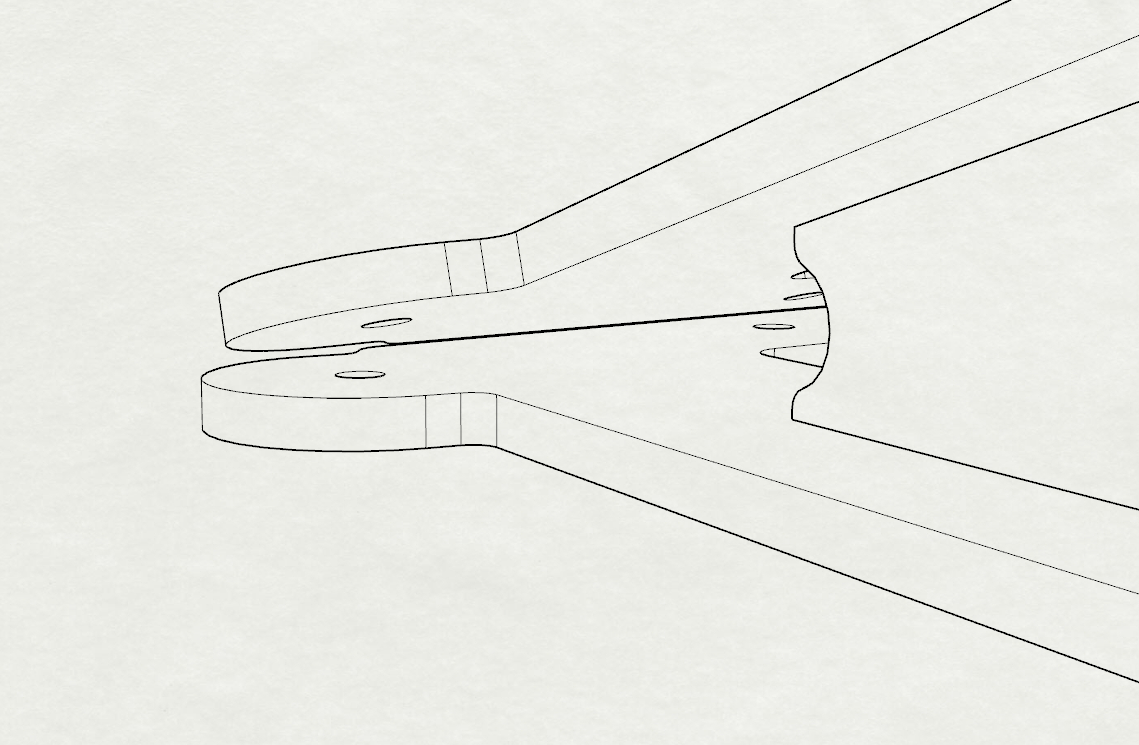

The original hardware gave me an idea of the size and layout of the first template. I traced and scanned the original hardware to create a general outline and measured the holes and angles precisely with calipers to ensure the prototype would fit correctly.

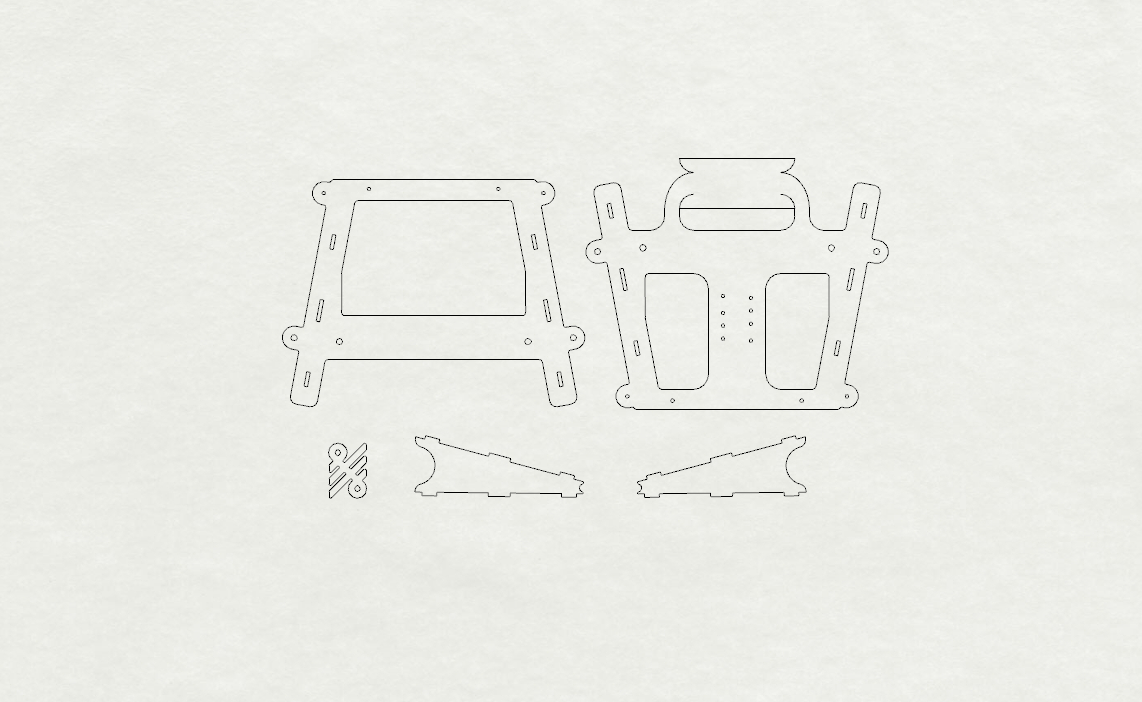

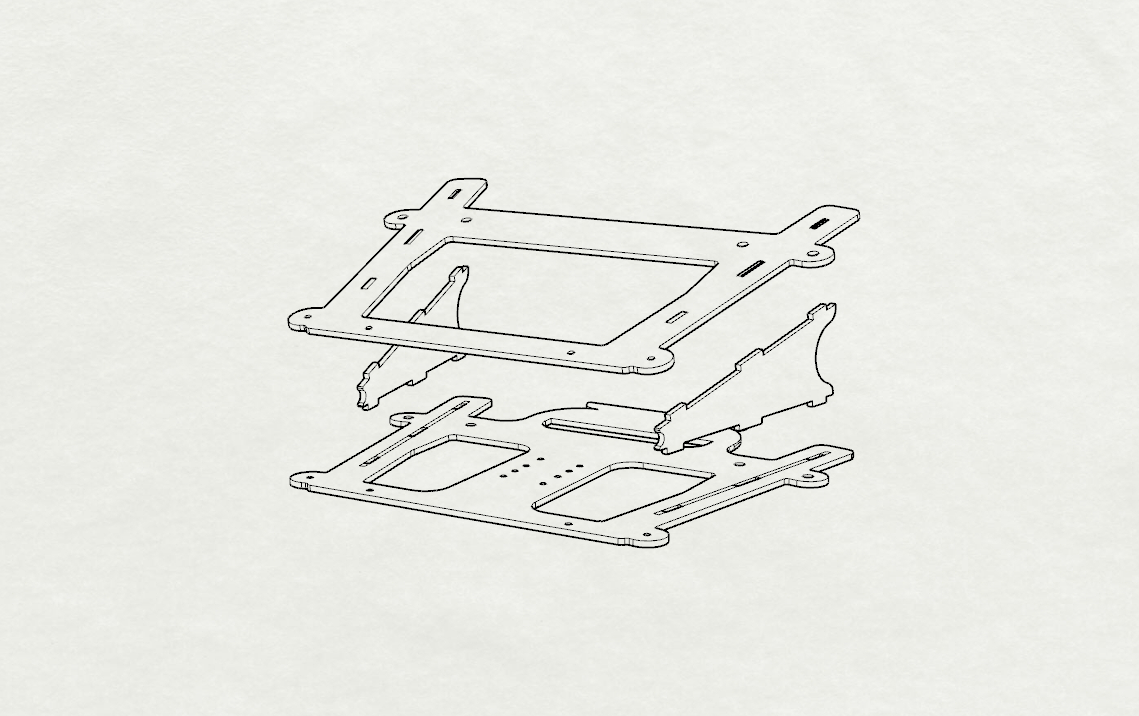

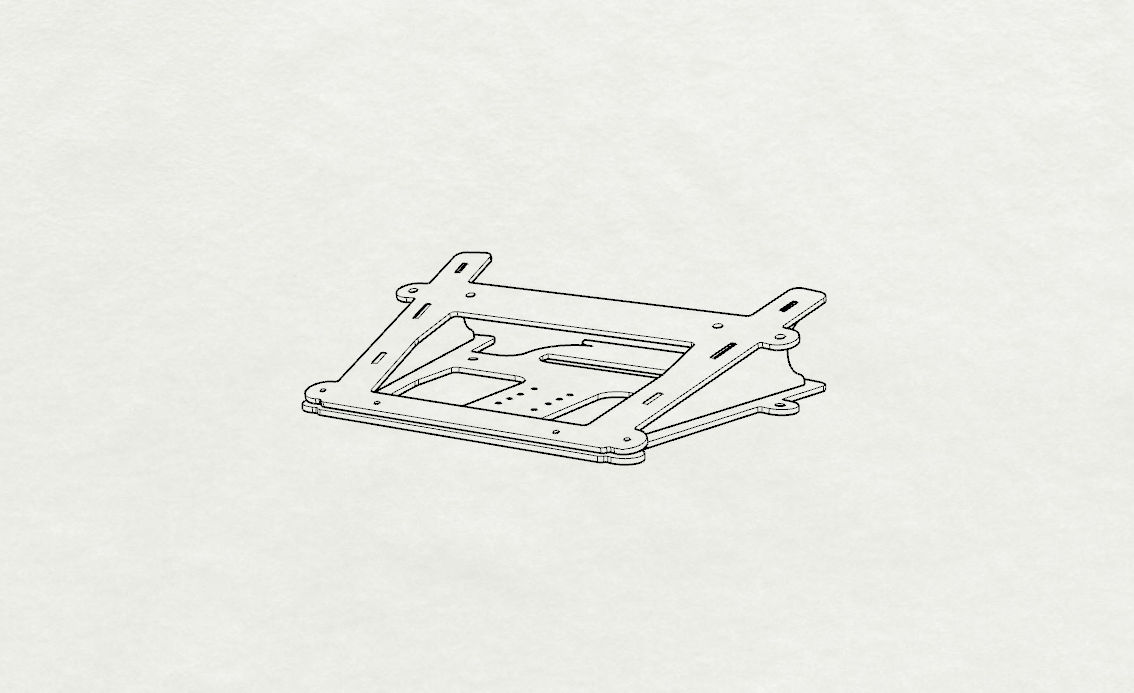

I needed to create an angled spacer that could attach to both the box and the original hardware, so the original hardware could still connect to the luggage rack. The bracket would lift the front of the box approximately 1 5/8 inches.

To ensure that the CAD model reflected reality, I traced the holes on the box and the original hardware and scanned the images. I used calipers to measure the distances between the holes to make sure that the photos I imported were the proper size.

Using the original hardware as a template helped considerably while developing my design. I added a handle to make carrying the box more manageable, which proved to be helpful.

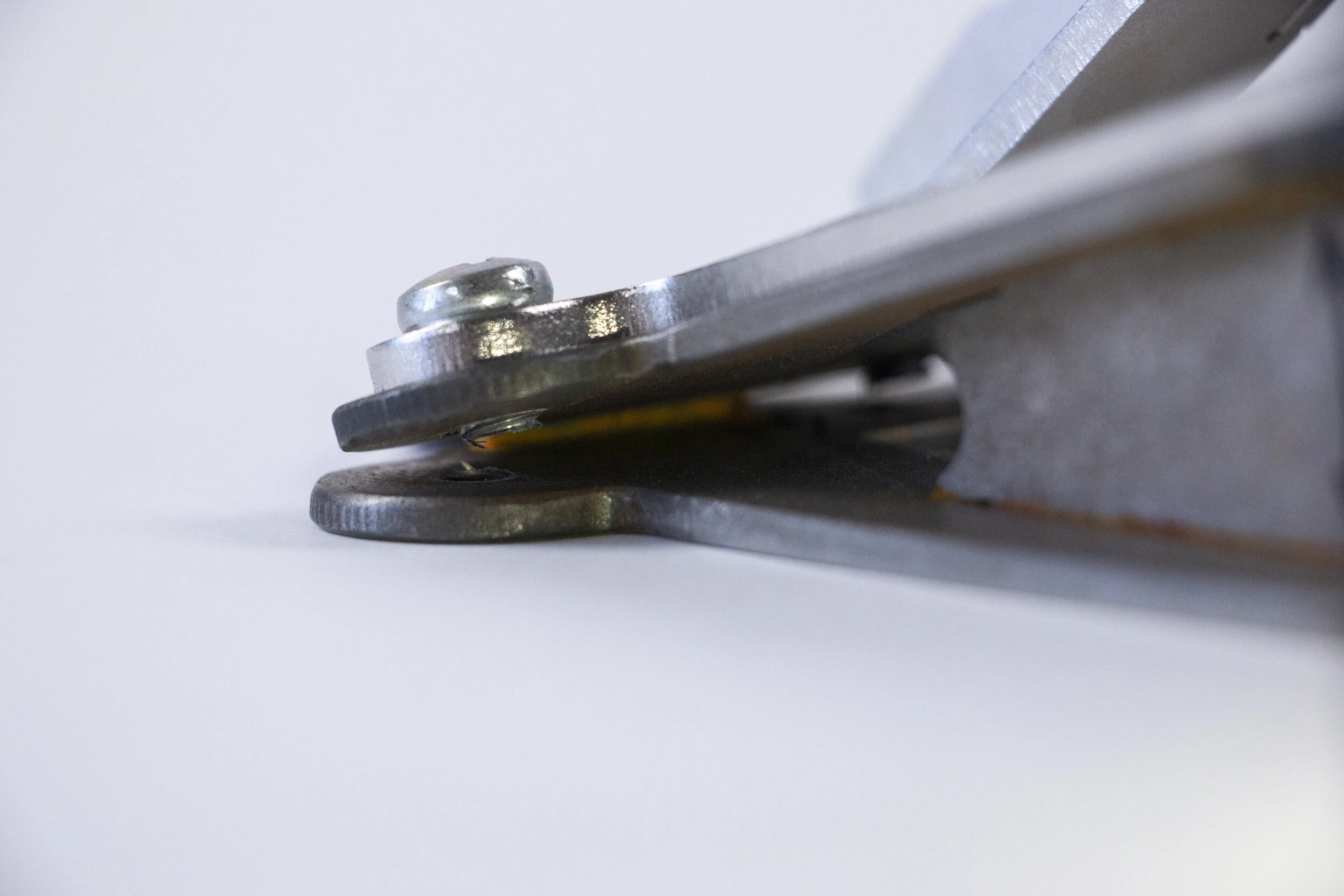

There were several things I didn’t anticipate during the prototype assembly. I didn’t leave any tolerance where the parts fit together. The handle was also difficult to bend into shape. On later prototypes, I will include cut lines to bend the metal more efficiently and accurately.

The issue with creating a spacer that both the original hardware and the box would mount on is the lack of room for nuts between the top and bottom plates. Due to the box latches and other spatial restrictions, the only option was to tap the 1/8” steel holes. I tested the tapped holes, and they held surprisingly well, but tapping the holes wasn’t a satisfactory solution. If the threads ever got cross-threaded or stripped, the only solution would be to drill it out and retap. The best solution is to have a nut in which the screw could thread. If anything happens to the nut or screw, it is easily replaceable.

Although this prototype functionally worked and made Wendy’s riding experience more comfortable, for my purposes, it wasn’t good enough. I wanted to create a product that I could manufacture efficiently, economically, drop-ship to a customer, and have them be able to open the box and install the product on their own quickly and with few tools. This prototype has four problems: tapping the holes is not secure, it is difficult to assemble, the handle is difficult to bend into shape, and the customer would have to grind the tip of their original brackets to make everything fit.