Prototype Two

The second prototype aimed to solve the problems of the first. Instead of using the original hardware in combination with my bracket, it would need to replace the original hardware.

The customer would be able to swap out one part for the other instead of needing to modify their original hardware and combine it with the new bracket.

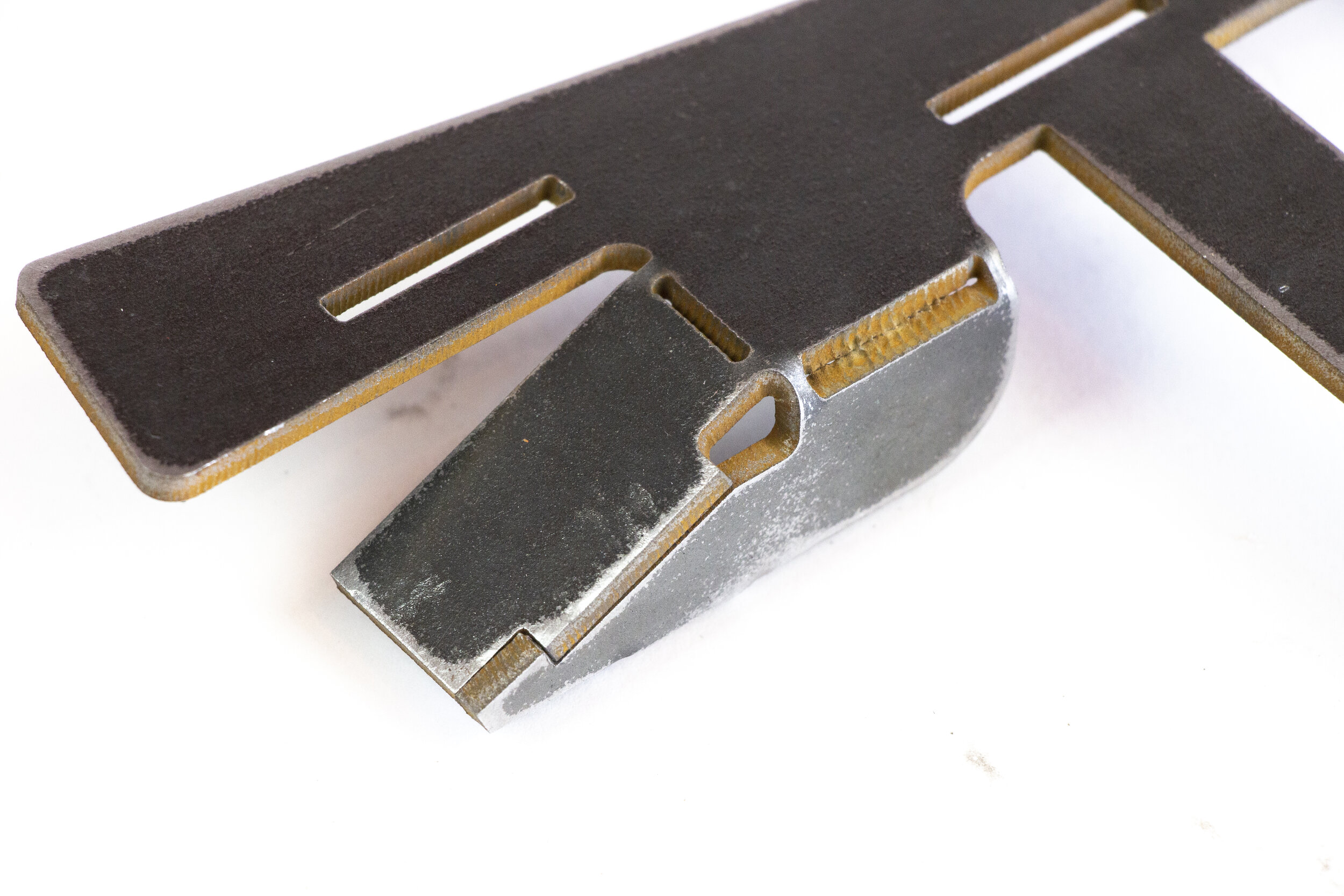

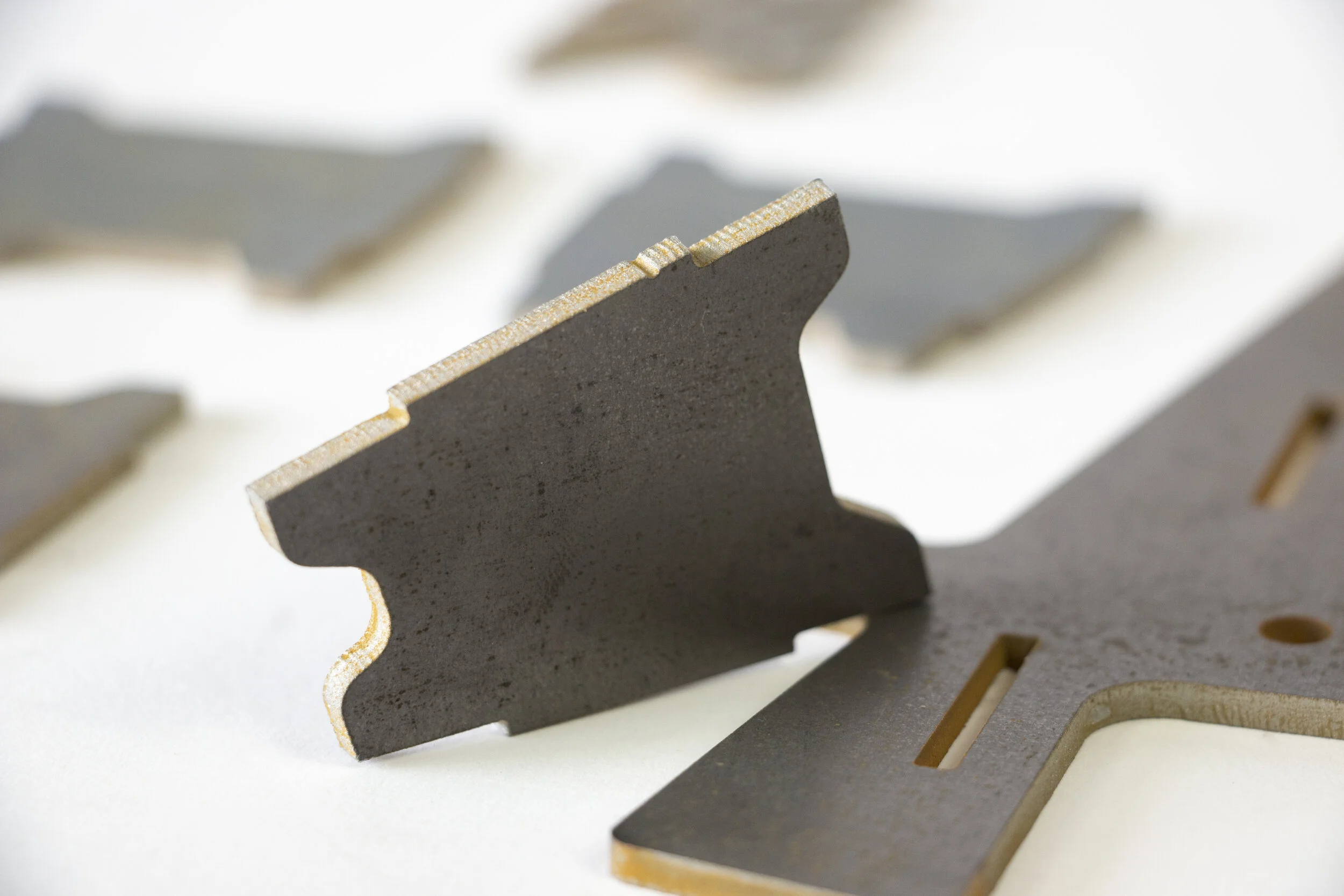

This bracket will now replace the original hardware. The screw holes intended for attaching to the original hardware are gone, the side parts are two pieces, and there are cut lines where the material needs to bend.

I designed the tabs to match those on the original hardware. Adding these tabs in my design also mitigates the issue of both nuts needing to occupy the same space as in the previous prototype.

The fold lines were cut to save time and increase accuracy during the manufacturing process. The fold line cuts are later welded to maintain material strength.

While assembling the prototype, the side parts had to be twisted and forced into place, so I made them into two pieces that aligned parallel to each other. Making this change solved the twisting issue and made the bracket much easier to assemble.

I added a hole above where the nut will be screwed. This hole will make the assembly much faster. If it were slightly larger, it could fit a standard 5/16” socket, so on the next prototype, I’ll make it bigger.